S,M,L,XL Environmentally friendly and soft. This white TPE glove (frosted pattern) is a high-perform...

See Details

Good temperature resistance Black TPE gloves (diamond pattern)

Black TPE gloves (diamond pattern) with good temperature resistance are high-performance disposable protective gloves that are both practical and professional. They are made of high-quality TPE (thermoplastic elastomer) materials. The gloves have good heat resistance and are suitable for work scenes with short-term contact with hot water, hot air or warm objects. The overall appearance is professional black, calm and generous, with good stain resistance, suitable for environments with high requirements for work image and cleanliness. The palm adopts a unique diamond-shaped anti-slip texture design with a larger friction area, which effectively improves the grip during operation, especially suitable for wet, greasy or precise operation conditions. The gloves are soft and thin, fit the hand shape, comfortable and flexible to wear, and are not easy to fatigue even after long-term use. The product does not contain latex and powder ingredients, is safe and non-irritating, and is suitable for sensitive skin. Disposable design, universal for both hands, convenient for high-frequency replacement, suitable for daily protection needs in various industries.

- Product Features

- Application Scenario

- Production Process

-

Black TPE gloves (diamond pattern) with good temperature resistance are suitable for a variety of operating environments that require short-term heat resistance or large temperature changes. They are widely used in hot dish assembly, catering kitchen cleaning, high-temperature sealing packaging, baking processing and other links in the food processing industry. They can also be used for operations involving heating, hot water washing or short-term contact with hot equipment in industrial production. In addition, the gloves are also suitable for beauty salons, electrical appliance maintenance, cleaning services, automobile maintenance and other industries. They play an effective heat insulation and protection role when exposed to hot air, electrical appliance surfaces, hot water or high-temperature tools. Its black appearance not only enhances the professional image, but also has good stain resistance and visual concealment. It is suitable for public services, high-end catering, experimental operations and other working environments with high requirements for appearance. The disposable environmentally friendly design reduces the risk of cross-contamination and is particularly suitable for daily use by enterprises and individuals who pursue efficiency, safety and sustainability.

-

Product features/advantages:

● Good temperature resistance: TPE material can withstand a certain temperature, suitable for short-term contact with hot water, steam and warm objects, ensuring safe operation.

● Diamond anti-slip pattern design: The palm adopts a three-dimensional diamond texture, which has more friction than the dot pattern, improving the grip stability and operation efficiency.

● Professional black appearance: calm and generous, strong stain resistance, improving the overall operation image, suitable for high-standard operation environment.

● Soft fit, comfortable to wear: the material is light and flexible, it fits the hand without being tight, and it is comfortable to use for a long time. Safe and anti-allergic: latex-free, powder-free formula, effectively prevents skin allergies and irritation, suitable for people with sensitive physiques.

● Disposable design, universal for both left and right hands: quick to put on and take off, no need to distinguish between left and right hands, suitable for high-frequency operation scenarios, and improve work efficiency.

● Environmentally friendly materials: TPE material is degradable and recyclable, in line with the concept of green production, and is the preferred choice for environmentally friendly hand protection products.

-

Technology and craftsmanship

The production technology and process of TPE gloves mainly involve material formula design, processing and molding methods and quality control system. Its core process features are as follows:

1. Material formula system

Substrate composition

● With SEBS (styrene-ethylene-butylene-styrene block copolymer) as the main base material, polyethylene resin (PE), plasticizer and other auxiliary materials are added through blending modification technology to form a composite material with both elasticity and strength.

● The proportion of SEBS directly affects the tensile strength and chemical resistance of gloves. The SEBS content in high-end medical-grade products can exceed 70%.

Functional Modification Additives

● Introducing antimicrobial agents to achieve the virus barrier function of medical-grade gloves;

● Adding antistatic agents improves applicability in industrial scenarios.

2. Core Processing Technology

Calendering process

● Suitable for the production of ultra-thin gloves. The molten TPE is formed into a continuous film through a calendering roller, and then cut and heat-sealed to complete the molding;

● The film thickness accuracy can reach ±0.01mm, meeting the food grade sealing requirements.

3. Comparison of process advantages

Process parameters

TPE cast gloves

PE blown film gloves

PVC Dipped Gloves

Molding temperature

180-220℃

130-160℃

160-190℃

Production cycle

30-60 seconds/double

15-20 seconds/double

5-8 minutes/double

Raw material utilization

>98%

85-90%

75-80%

Recyclability

100% recyclable

Not recyclable

Partial recovery requires dechlorination

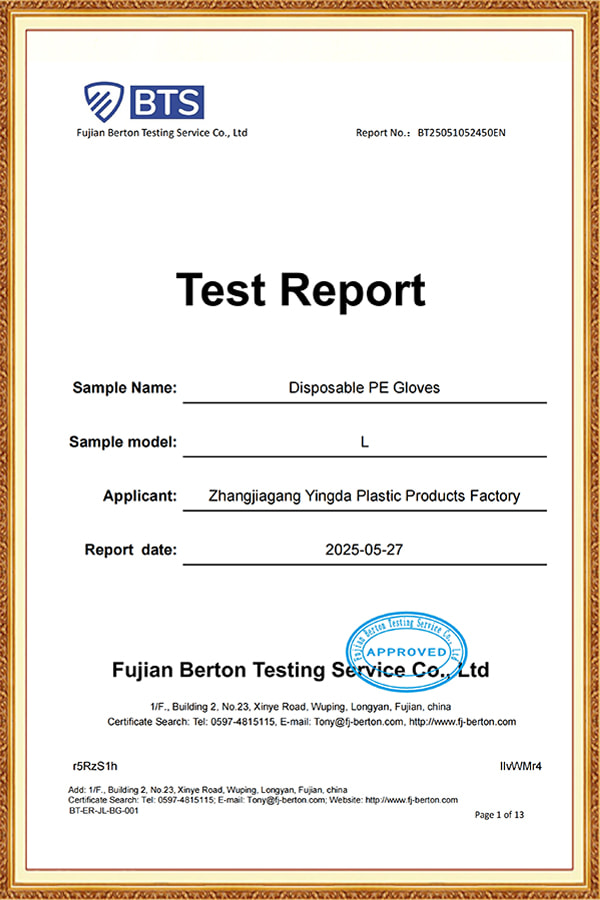

4. Key points of quality control

Physical performance testing

● Tensile strength ≥18MPa, elongation at break>500%;

● Thickness uniformity error <5%.

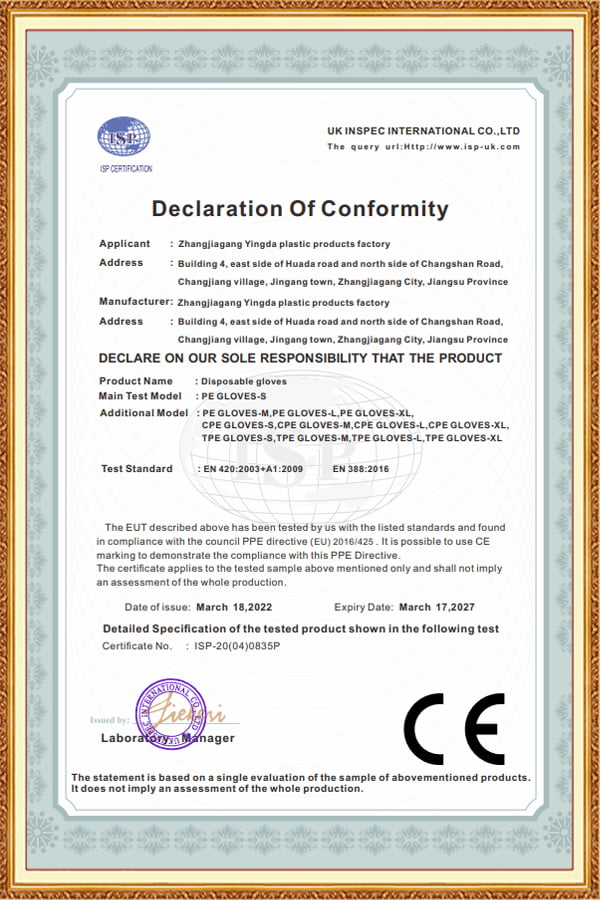

Chemical Safety Certification

● Passed FDA 21CFR 177.2600 food contact material certification;

● Complies with EU REACH regulations (SVHC < 0.1%) and RoHS Directive.

Microbial Barrier Test

● Medical-grade products must pass the ASTM F1671 virus penetration test, with a barrier efficiency of ≥99.8%.

5. Typical application adaptation process

● Medical- grade gloves: Adopt casting + post-sterilization process to ensure sterility;

● Food -grade ultra-thin gloves: 0.03mm thick products are produced by calendering process, with a transmittance of >90%.

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory resea...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, poly...

READ MORE -

Introduction In today’s fast-paced world, the need for disposable gloves has become more apparent than ever. Whether in the food industry, healthcare, or everyday home use, disposa...

READ MORE

English

English  Français

Français  Deutsch

Deutsch