S,M,L,XL Environmentally friendly and soft. This white TPE glove (frosted pattern) is a high-perform...

See Details

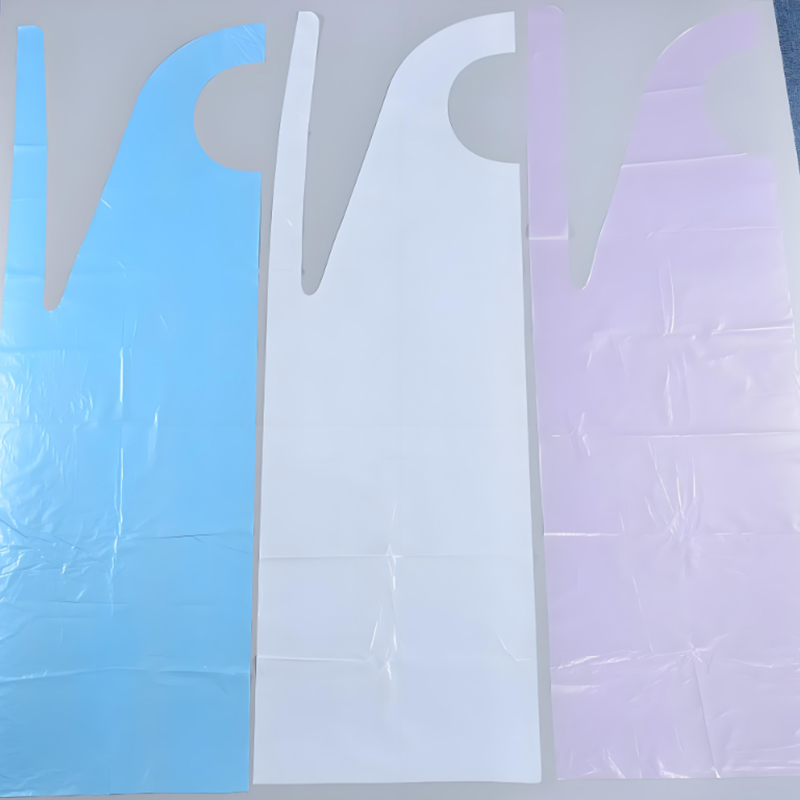

Creamy white PE apron

Product Description PE Apron is a disposable protective clothing made of polyethylene (PE) material, which has the characteristics of lightness, durability, waterproof and oil-proof. PE aprons are usually made of LDPE, HDPE or LLDPE and are made by film blowing. Its manufacturing process involves extruding polyethylene granules into sheets, which are then cut into apron shapes, and advanced manufacturing technology is used to ensure the uniform thickness and strength of the product.

● Product Features Chemical resistance and waterproofness: PE aprons have excellent resistance to liquids, oils and other pollutants, can effectively prevent the penetration of water, oil and other chemicals, and are suitable for various industrial environments.

● Durability and Strength: Despite being lightweight, PE aprons have remarkable tear resistance and strength, able to withstand rigorous industrial environments and are not easily torn or punctured.

● Comfort and Health: Designed with comfort in mind, the PE apron features adjustable neck and waist ties to fit different body types, and is hypoallergenic, reducing the risk of allergic reactions.

● Economical and Environmentally Friendly: PE aprons are disposable products, eliminating the need for washing and maintenance, and bulk purchases further reduce costs, making them suitable for large-scale operations.

- Product Features

- Application Scenario

- Production Process

-

Application scenarios Healthcare industry:

In the healthcare field, PE aprons are an important part of personal protective equipment (PPE). They resist bodily fluids, pathogens and other contaminants, reducing the risk of cross-contamination and spread of infection. Studies have shown that the use of disposable PE aprons can significantly reduce the incidence of hospital-acquired infections (HAIS) and improve patient safety and quality of care.

● Food Industry: In food processing and catering services, PE aprons are used to prevent food contamination. They effectively create a hygienic barrier between workers and food, complying with strict food safety regulations. The waterproof nature of the PE apron ensures that any spills or splashes will not penetrate the garment, thus maintaining personal hygiene and product integrity.

● Industrial and Manufacturing Environments: In industrial environments, workers are often exposed to substances such as oils, lubricants, and dust. PE aprons offer a protective solution, keeping workers' clothing clean while preventing contamination.

● Home and Daily Use: PE aprons are also suitable for daily scenes such as home kitchens and cleaning work. They are waterproof and oil-proof, easy to carry and use, and are particularly suitable for family gatherings or restaurant environments. They can greatly reduce the workload of cleaning and improve efficiency.

● Laboratories and Diagnostic Centers: In laboratories and diagnostic centers, technicians often handle chemical reagents and biological samples. PE aprons protect them from accidental spills and splashes, ensuring the safety of experiments and tests.

-

Product characteristics and advantages.

● Easy to wear: PE aprons are easy to wear and can be thrown away directly after use without washing, saving cleaning costs.

● Waterproof and Oilproof: PE aprons have good waterproof and oil-proof properties, and can effectively prevent the penetration of liquids, oils and other pollutants. This feature is particularly important in industries such as food processing and medical services to prevent cross contamination. .Acid and alkali resistant: PE aprons are resistant to acid and alkali and can provide protection in chemical environments.

● Lightweight and Durable: Although the PE apron is lightweight, it has remarkable strength and tear resistance, able to provide effective protection in industrial environments without the need for frequent replacement.

● Cost Effective: PE aprons are disposable, eliminating the need for washing or maintenance, bulk purchases further reduce costs, suitable for large-scale operations.

● Comfort: Designed with various sizes and adjustable neck and waist straps, the PE aprons provide a comfortable wearing experience and help workers follow safety protocols.

● Hypoallergenic: PE apron material is hypoallergenic, reducing the risk of allergic reactions for users, which is especially important in the healthcare industry.

-

1. Raw materials and preparation technology

Basic material selection

● LDPE (low-density polyethylene) and HDPE (high-density polyethylene) are used as the main raw materials, and the balance between flexibility and strength is achieved by adjusting the ratio of the two materials16. LLDPE (linear low-density polyethylene) is added in some processes to improve tear resistance.

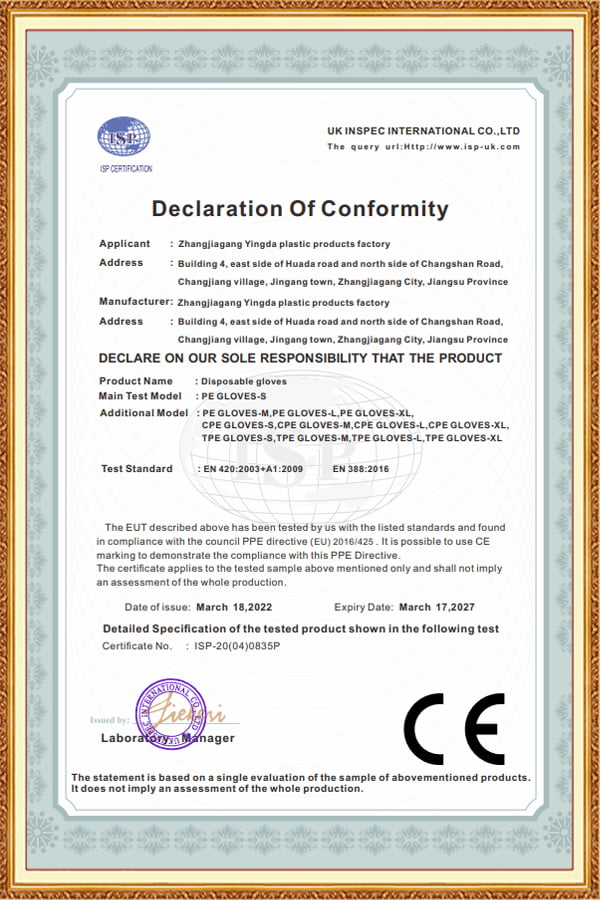

● The raw materials must meet the food contact safety standards and do not contain heavy metals (such as lead, chromium) and allergens. Film production process

● Blowing process : The molten polyethylene is extruded into a tubular film bubble through an extruder, and a film of uniform thickness is formed through the steps of blowing, cooling, and pulling. The key process parameters include extrusion temperature (160-190°C), blowing ratio (controlling the diameter of the film bubble) and pulling ratio (affecting the longitudinal strength).

● Embossed treatment : The surface of the film is pressed with concave and convex patterns or smoothed to enhance the anti-slip and durability.

2. Product molding and function optimization

Stamping molding technology

● A one-time stamping molding process is adopted, and the film is directly cut through the mold to form the apron contour to reduce the loss of scraps.

● Support customized design, including size (such as 28"x46"), thickness (0.008-0.045mm), color and surface texture. Functional enhancement technology

● Waterproof and oil-proof treatment: Enhance liquid barrier properties through the hydrophobicity of polyethylene itself and surface coating process.

● Chemical resistance improvement: Add additives to improve acid and alkali resistance and adapt to special environments such as medical and chemical industries.

● Environmental innovation: Introduce degradable polyethylene materials or RPET recycled fibers (such as recycled PET bottles to make yarn) to reduce environmental burden. III. Process control and quality assuranceKey technical parameters

● Uniformity control: Ensure the consistency of film thickness through automated film blowing equipment to avoid local weak points.

● Cooling and curing: Accurately control the position of the "dew point" (frost line) to optimize the crystallinity and mechanical properties of the film. Quality inspection

● Includes tear strength test, liquid permeability verification and hygiene and safety testing (such as microbial indicators).

● Equipment needs to be calibrated regularly during production to prevent defects such as crystal points and melt fracture. IV. Application adaptation and innovation trends

● Adjustable design: Removable waist straps and neck straps are used to achieve personalized adaptation and improve wearing comfort.

● Scenario customization: For example, the medical field uses high-cleanliness aprons produced in dust-free workshops, and the catering field adds ventilation hole design.

● Intelligent production: Explore automated winding and printing integrated equipment to improve customization efficiency

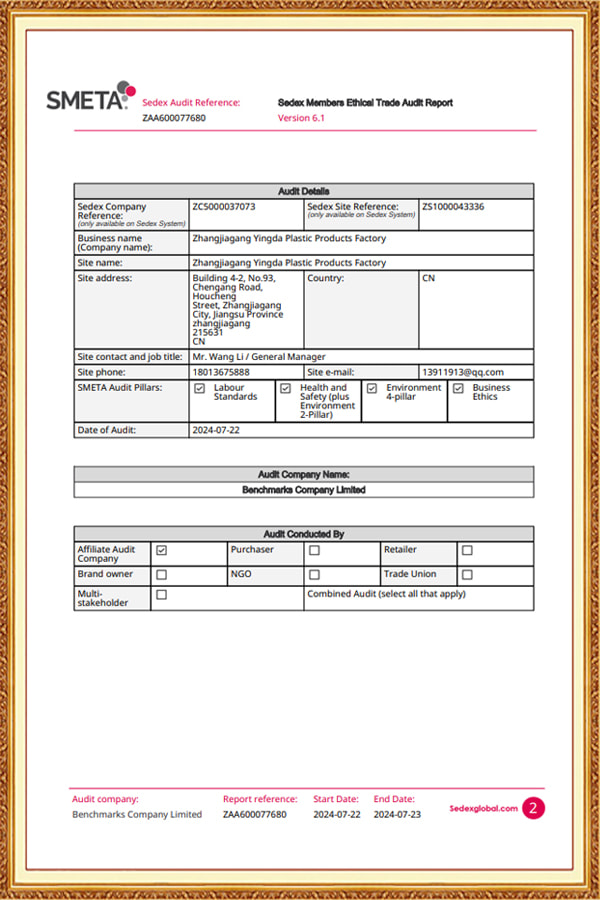

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory resea...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, poly...

READ MORE -

Introduction In today’s fast-paced world, the need for disposable gloves has become more apparent than ever. Whether in the food industry, healthcare, or everyday home use, disposa...

READ MORE

English

English  Français

Français  Deutsch

Deutsch