S,M,L,XL Environmentally friendly and soft. This white TPE glove (frosted pattern) is a high-perform...

See Details

Anti-bacteria, acid and alkali resistant Blue HDPE gloves

Anti-bacteria, acid and alkali resistant blue HDPE gloves are disposable gloves made of high-density polyethylene (HDPE) material, which are waterproof, oil-proof, anti-bacteria and acid-alkali resistant. This type of gloves is produced through a blown film pressing process, and the surface is specially processed. It not only has good anti-slip properties, but can also be used with both hands. It is easy to use and economical. It is widely used in many fields such as household cleaning, laboratories, food processing, mechanical gardening, etc., and is an indispensable protective product in daily life.

- Product Features

- Application Scenario

- Production Process

-

Anti-bacterial, acid-resistant and alkali-resistant blue HDPE gloves are suitable for a variety of scenarios, including but not limited to the following areas:

● Household cleaning and care: used for washing dishes, cleaning the kitchen or handling large bones to avoid direct contact with dirt and bacteria.

● Laboratory and medical fields: isolate bacteria and chemicals during experimental operations to protect experimenters from contamination.

● Food processing and sanitation industry: used in food processing, packaging and food inspection to ensure food safety.

● Industrial and agricultural protection: provide hand protection in environments such as machinery maintenance, gardening operations and chemical plants to prevent acid and alkali solutions or oil stains from damaging the skin.

-

Product Features:

Material and technology:

Made of HDPE raw material, made by film blowing and pressing process, the surface is processed with concave and convex processing, with anti-slip and anti-adhesion functions, and supports mixed use of left and right hands.

● Waterproof and oil-proof: effectively prevent liquid penetration and oil adhesion to ensure hand cleanliness.

● Acid and alkali resistance: can resist the erosion of various acid and alkali solutions, suitable for chemical plants and laboratory environments.

● Antibacterial performance: surface treatment technology can inhibit bacterial growth and protect the health of users.

● Convenience of use: light, thin and soft, easy to put on and take off, suitable for long-term wear without affecting flexibility. Economical: disposable, no need for repeated cleaning or disinfection, reducing the cost of use.

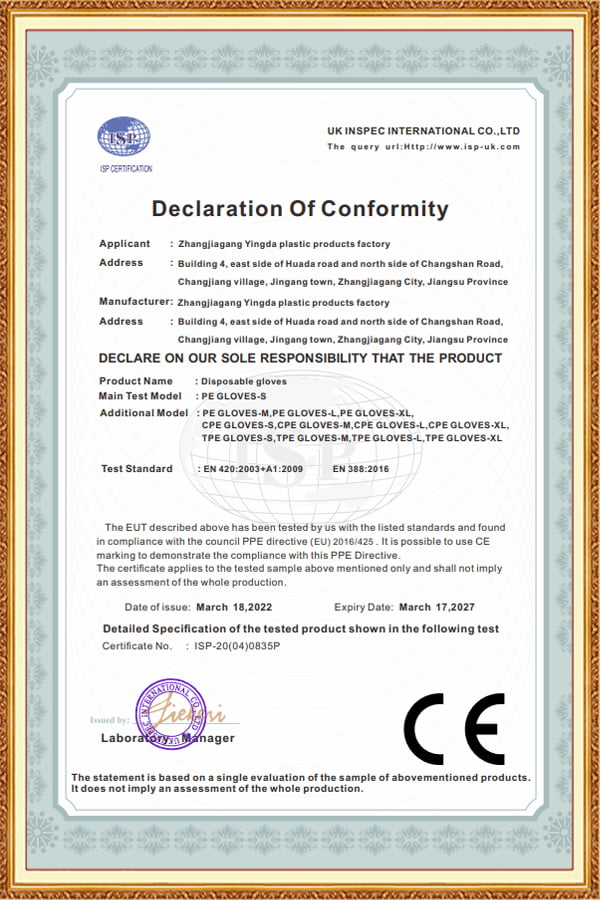

● Environmentally friendly and safe: does not contain natural latex ingredients, non-toxic and harmless, suitable for people with allergies.

-

Technology and craftsmanship

1. Core production process

Raw material ratio and pretreatment

PE gloves are mainly made of LDPE (low-density polyethylene), HDPE (high-density polyethylene) or LLDPE (linear low-density polyethylene) raw materials, which are mixed with additives (such as plasticizers and anti-sticking agents) to form a homogeneous material. Some processes introduce composite modification technology to improve barrier properties (such as oil resistance and chemical resistance).Film blowing

molding: After the mixed raw materials are melted at high temperature in a blow molding machine, they are extruded through a ring die to form a tubular PE film. The film thickness is controlled by air pressure and traction speed, and the thickness accuracy can reach ±0.01mm^[2][8]. The film blowing technology directly determines the uniformity and mechanical properties of the gloves.Mold hot pressing molding

uses a reciprocating finger mold to hot press the PE film. The mold temperature is controlled at 120-150℃, the pressure is about 0.5MPa, and the molding time is 0.5-1 second, which can achieve rapid separation of disposable gloves. The automated mold system can achieve a pressing efficiency of 200-300 gloves per minute.Separation and Packaging

The formed gloves are automatically separated from the waste by pneumatic grippers, and the defective products are removed by the visual inspection system. Before packing the qualified products, triple packaging (plastic film + box + outer box) is carried out to ensure hygiene and safety.2. Key technical improvements

● Anti-slip structure design : Adding pitting or texture on the mold surface increases the friction coefficient of the gloves and improves the anti-slip performance by more than 40% (laboratory test data).

● Process energy saving optimization: Using low-temperature film blowing technology (melting temperature reduced by 15°C), energy consumption is reduced by 20% while avoiding material degradation.

● Waste recycling system: The recycling ratio of scraps after crushing reaches 30%, reducing the raw material cost by 10%-15%.

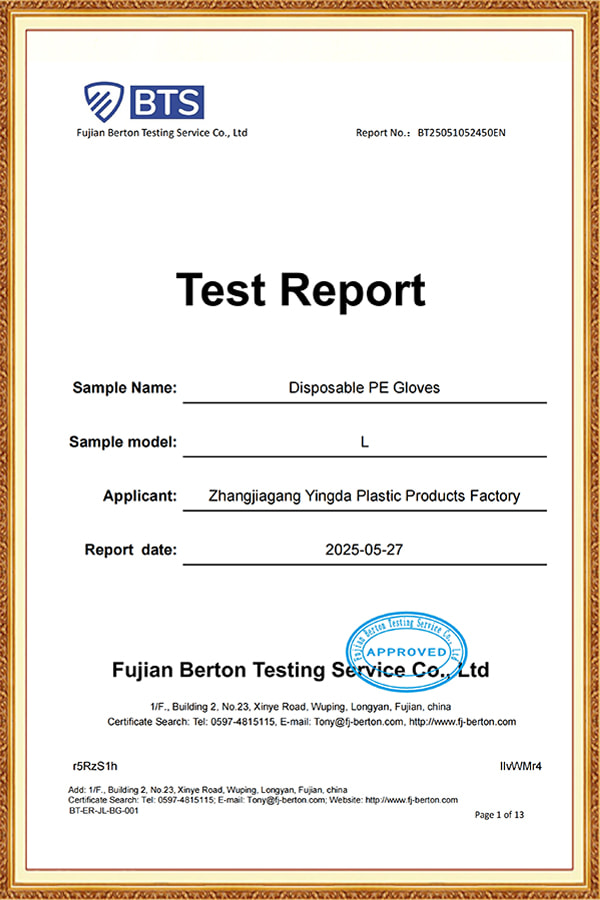

3. Performance indicators and quality control

● Physical properties: tensile strength ≥8MPa, elongation at break ≥300% (GB/T 1040.3 standard);

● Chemical protection: Passed 24-hour 10% salt water immersion test, water permeability <2.1g/m²·24h;

● Hygiene Control: The production environment complies with ISO 14644-1 Class 8 cleanliness requirements, and the finished products are sterilized with ethylene oxide.

4. Application adaptability analysis

● Low-cost scenarios: The cost of a single PE glove is about 0.02 yuan, which is suitable for light-load scenarios such as catering sorting and short-term cleaning;

● Limitations: The upper temperature limit is 60°C. It is easily damaged when exposed to organic solvents or sharp objects. It is not suitable for medical surgery and other fields with high protection requirements.

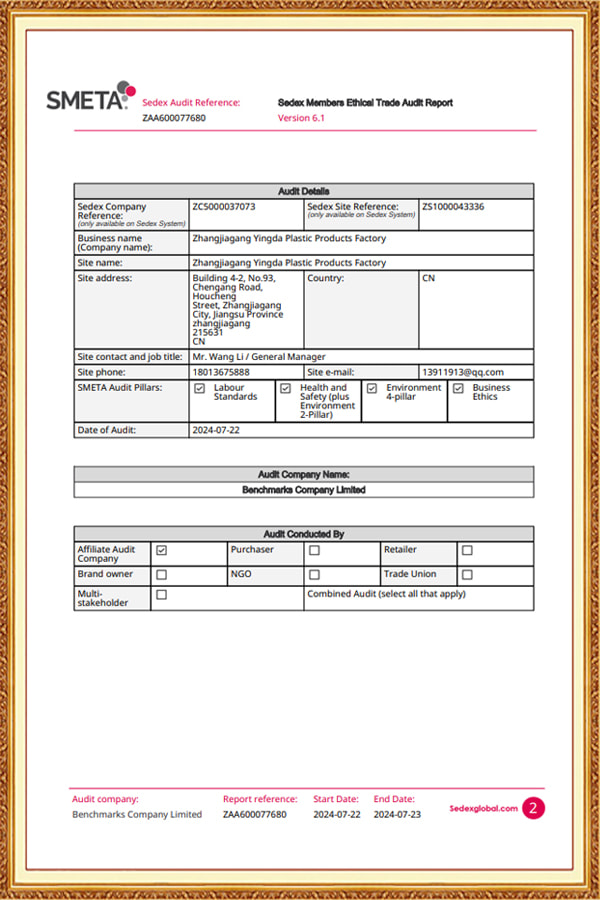

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory resea...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, poly...

READ MORE -

Introduction In today’s fast-paced world, the need for disposable gloves has become more apparent than ever. Whether in the food industry, healthcare, or everyday home use, disposa...

READ MORE

English

English  Français

Français  Deutsch

Deutsch