Custom Disposable HDPE Gloves Manufacturers

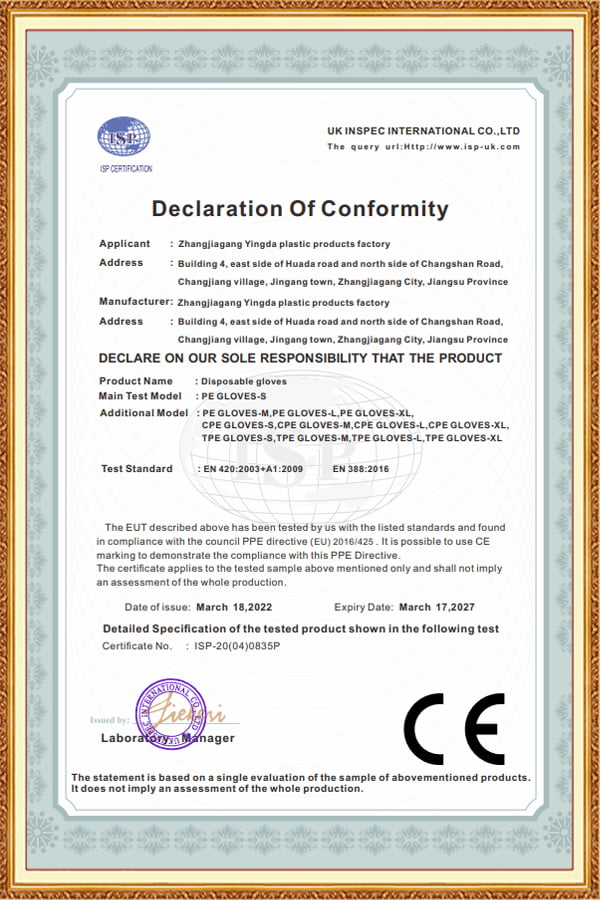

HDPE gloves (high-density polyethylene gloves) are known for their durability and toughness and are an important type of PE gloves. The material is hard and light, has high tensile strength, and is not easily pulled or torn, so it is particularly suitable for occasions that need to withstand greater pressure or mechanical wear. HDPE gloves are usually thinner, but their chemical resistance and tear resistance are better than LDPE gloves, so they are widely used in industry, laboratories, food processing and other fields. HDPE gloves are mostly produced using the blown film process, and the surface often has an embossed design to increase anti-slip performance. They also have the characteristics of being waterproof, oil-proof, acid-resistant and alkali-resistant. In addition, HDPE gloves also have good heat resistance and can maintain stable performance within a certain temperature range. This type of gloves is usually used in environments where protection is required, such as laboratory operations, mechanical gardening, food hygiene processing, etc.

HDPE Gloves

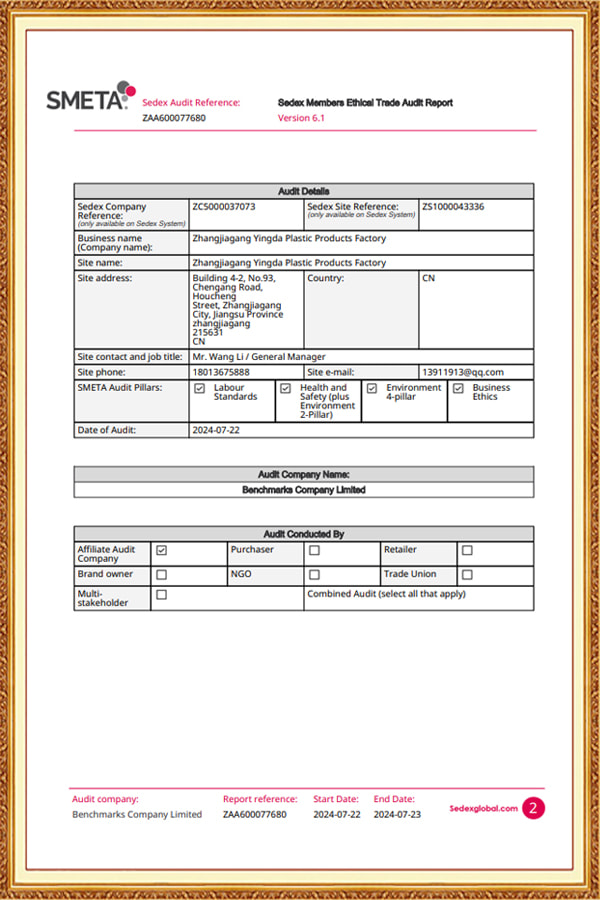

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. From food processing and medical settings to cleaning operations and light manufacturing, disposable gloves have become ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory research, hospitality, and industrial manufacturing. Among the most widely used protective garments are polyethylene aprons a...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, polyethylene film has become an indispensable material due to its unique balance of strength, flexibility, chemical resistan...

READ MORE

In what emerging fields are high-density polyethylene (HDPE) disposable gloves expected to be used?

High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves are famous for their durability and toughness. They are hard and light, with high tensile strength and are not easy to be pulled or torn. Zhangjiagang Yingda Plastic Products Factory has strict control over every link from mold development to finished products through advanced production line layout to ensure that the High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves produced are excellent in durability. They are especially suitable for industrial occasions that need to withstand greater pressure or mechanical wear, such as automobile manufacturing, mechanical processing, etc., and can effectively protect workers' hands from harm. Its chemical resistance is better than LDPE gloves and can resist the erosion of various chemicals such as acids and alkalis. In laboratory operations, scientific researchers often come into contact with various chemical reagents. Zhangjiagang Yingda Plastic Products Factory's High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves have excellent chemical resistance due to continuous technological innovation, providing reliable protection for experimenters and ensuring the safety of experiments. The waterproof and oil-proof properties of High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves make them very useful in the field of food processing, which can prevent food from being contaminated and ensure food safety. It also has good heat resistance and can maintain stable performance within a certain temperature range, which makes its application scenarios more extensive. The factory also supports personalized customization, and adjusts the thickness, size, anti-slip design, etc. of gloves according to the needs of different industries to meet the special requirements of various industries for gloves.

What are the characteristics of the production process of High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves?

Zhangjiagang Yingda Plastic Products Factory puts HDPE raw materials into the film blowing machine. Under the action of high temperature and high pressure, the white HDPE particles become elongated films. The factory has established a full-process production line from mold development, stamping, heat treatment, surface treatment to equipment, and accurately controls the temperature, pressure and other parameters in the film blowing process to ensure that the produced film has uniform thickness and stable quality, laying a good foundation for subsequent glove molding. In order to enhance the anti-slip performance, the surface of HDPE gloves usually adopts an embossed design. Through continuous technological innovation, the factory has developed a variety of unique embossed patterns, which can not only effectively improve the anti-slip effect of gloves and provide better grip during operation, but also ensure anti-slip while not affecting the flexibility and wearing comfort of gloves, meeting the anti-slip performance requirements of gloves in different work scenarios.

What are the advantages of High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves compared with gloves made of other materials?

Compared with some high-performance material gloves, High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves have relatively low costs. Zhangjiagang Yingda Plastic Products Factory relies on advanced production management mode and cost control system to optimize production process, reduce raw material loss, and further reduce the production cost of HDPE gloves. This makes HDPE gloves more competitive in price while meeting protection needs, suitable for large-scale use, such as in food processing enterprises, the large-scale use of HDPE gloves can effectively control costs. Compared with LDPE gloves, HDPE gloves have stronger chemical resistance and tear resistance. In industrial production, such as chemical companies, workers may be exposed to various chemicals. Zhangjiagang Yingda Plastic Products Factory's High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves can provide workers with more reliable protection and reduce the risk of chemical injuries to their hands; in mechanical gardening, in the face of branches, tools, etc. that may tear the gloves, the tear resistance of HDPE gloves can also better protect the hands of users.

What strengths does the factory have in the customization of High-Density Polyethylene (HDPE) disposable gloves, disposable HDPE gloves?

With key processes and technologies, a multi-unit support system for cost control, quality management, and efficiency optimization has been built. Whether it is the thickness, color, size of the gloves, or special functional requirements, such as anti-static treatment, special anti-slip design, etc., accurate customization can be achieved through advanced production line layout and continuous technological innovation. Starting from mold development, it is designed according to customer customization requirements to ensure that the mold accurately meets the customized specifications of the gloves. The stamping, heat treatment, surface treatment and other links are also closely centered around customization requirements. Every link is strictly controlled for quality to ensure that the customized HDPE gloves can meet customer expectations in terms of dimensional accuracy, protective performance, appearance, etc., and provide customers with high-quality customized products.

English

English  Français

Français  Deutsch

Deutsch