S,M,L,XL Environmentally friendly and soft. This white TPE glove (frosted pattern) is a high-perform...

See Details

Waterproof, non-slip and breathable Blue CPE gloves

Blue CPE gloves are disposable protective gloves made of polyvinyl chloride (CPE) material, which are waterproof, anti-slip, breathable and suitable for a variety of industrial and daily use scenarios. This type of gloves is made by film blowing process, and the surface is specially treated to have good anti-slip and waterproof effects, while maintaining high breathability to ensure the comfort of the wearer's hands during use.

- Product Features

- Application Scenario

- Production Process

-

Blue CPE gloves can be used in many fields such as beauty and hairdressing, household cleaning, mechanical gardening, food processing, sanitation and epidemic prevention, chemical protection, etc. They are especially suitable for working environments that need to protect hands from oil and bacterial contamination.

-

The main features of blue CPE gloves include:

● Waterproof and anti-slip: The surface is designed with anti-slip patterns or coatings, which can effectively prevent the hands from slipping during operation. At the same time, it has good waterproof performance and is suitable for occasions in contact with liquids or humid environments.

● Breathable: The gloves are made of breathable materials, which can keep hands dry and reduce discomfort even when worn for a long time.

● Environmentally friendly and healthy: CPE material is non-toxic and odorless, does not contain plasticizers, meets environmental protection requirements, and is suitable for food processing, laboratories and other fields with high hygiene requirements.

● Durability: CPE material has high strength and wear resistance, is not easy to break or damage, and is suitable for repeated use or high-intensity working environments.

-

3. Technology and craftsmanship

CPE gloves technology and process analysis

1. Core production process

Material System and Pretreatment

CPE gloves are made of a blended modified material of chlorinated polyethylene (CPE) and polyethylene (PE ) , and the flexibility and chemical resistance are improved by adding additives. Different from the single polyethylene material of traditional PE gloves, CPE composite materials enhance the barrier properties and mechanical strength through vinyl chloride copolymerization modification.Film blowing and dipping molding:

The blended material is melted at high temperature and then formed into a basic film material through a film blowing process. Some processes use a dipping method combined with mold forming technology to achieve thickness uniformity control (thickness can reach 0.08-0.12mm) by dipping into a curing agent bath multiple times^[3][6]. The mold surface can be designed with anti-slip patterns to increase the friction coefficient of the gloves.Vulcanization and Sterilization

The gloves after molding need to go through the vulcanization process (high temperature and high pressure environment) to enhance the cross-linking degree of rubber molecules, improve tensile strength and elasticity. Finally, ethylene oxide gas or gamma ray sterilization is used to ensure that the product meets food grade or medical grade hygiene standards.2. Key Technology Breakthroughs

● Composite modification technology: CPE and PVC are blended to achieve triple protection of water resistance, oil resistance and solvent resistance. The water permeability can be as low as 2g/m²·24h, and the oil-proof penetration time is more than 30 minutes (laboratory test data);

● Functional coating: Some high-end products introduce food-grade antibacterial coatings that can directly contact food and inhibit bacterial growth;

● Extended Arm Guard Design: The 60cm extended version of the gloves covering the elbows adopts a segmented pressure-sealed process to ensure that the protection range is extended while maintaining flexibility.

3. Quality Control Standards

● Physical properties: tensile strength ≥10MPa, elongation at break ≥400%, wear resistance is more than 30% better than ordinary PE gloves;

● Chemical protection: Passed 24-hour 10% acid and alkali solution immersion test, no penetration, no damage;

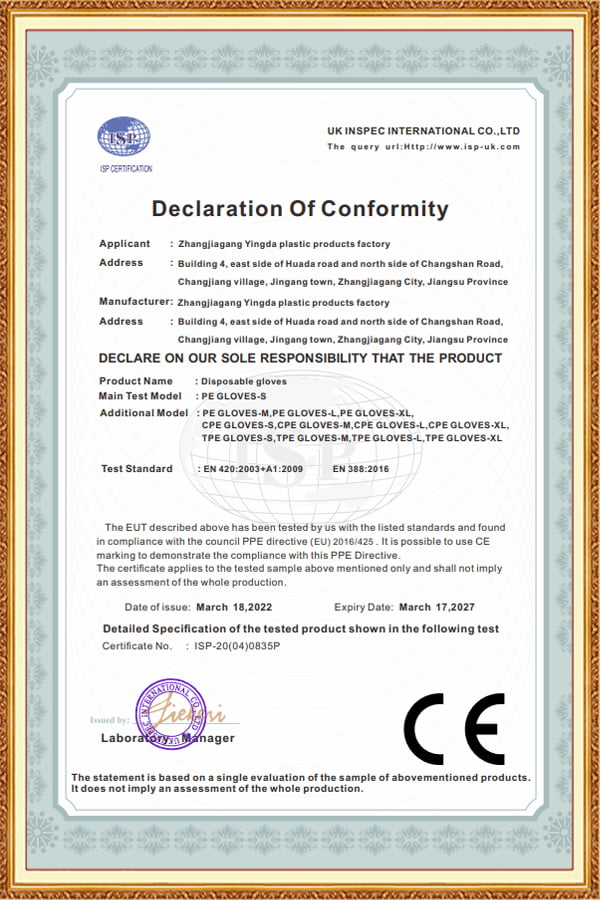

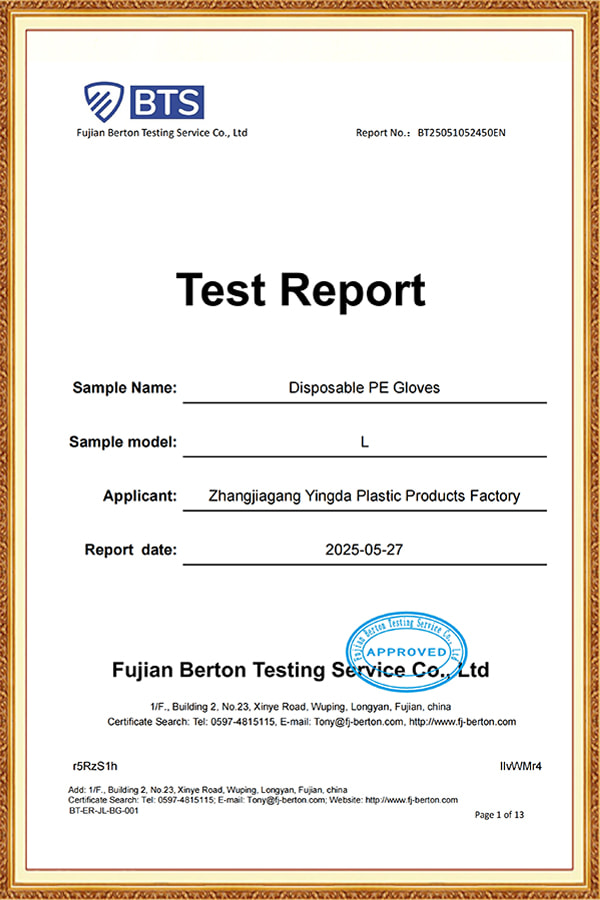

● Sanitary Certification: Meets FDA food contact material standards, and some products have passed CFDA medical device certification.

4. Comparison with PE gloves

Characteristic

CPE Gloves

Ordinary PE gloves

Material Cost

High (including blending and modification process)^[1][3]

Low (single polyethylene material)^[1][8]

Protection performance

Waterproof/oilproof/chemical resistant^[3][5]

Only basic waterproof and moisture-proof^[1][8]

Applicable scenarios

Food processing, chemical protection, medical care^[3][5]

Scenarios requiring short-time cleaning and lightweighting^[1][8]

Durability

Can be reused 2-3 times^[5][7]

Single-use, easily damaged^[1][8]

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory resea...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, poly...

READ MORE -

Introduction In today’s fast-paced world, the need for disposable gloves has become more apparent than ever. Whether in the food industry, healthcare, or everyday home use, disposa...

READ MORE

English

English  Français

Français  Deutsch

Deutsch