Custom Dotted Embossed Disposable TPE Gloves Manufacturers

TPE gloves (dot pattern) are disposable gloves made of thermoplastic elastomer with a unique dot pattern design. This type of glove is widely popular for its excellent performance and comfort, and is especially suitable for home cleaning, food processing, medical care and other scenarios. The design of TPE gloves fully considers the principles of ergonomics. The finger parts use elastic blocks and solidified dot blocks, which can adapt to different finger lengths and provide better fit and flexibility. In addition, its dot pattern not only improves the grip, but also enhances the anti-slip performance of the ground, avoiding the risk of falling due to wetness and slippery.

TPE Gloves (Dot Pattern)

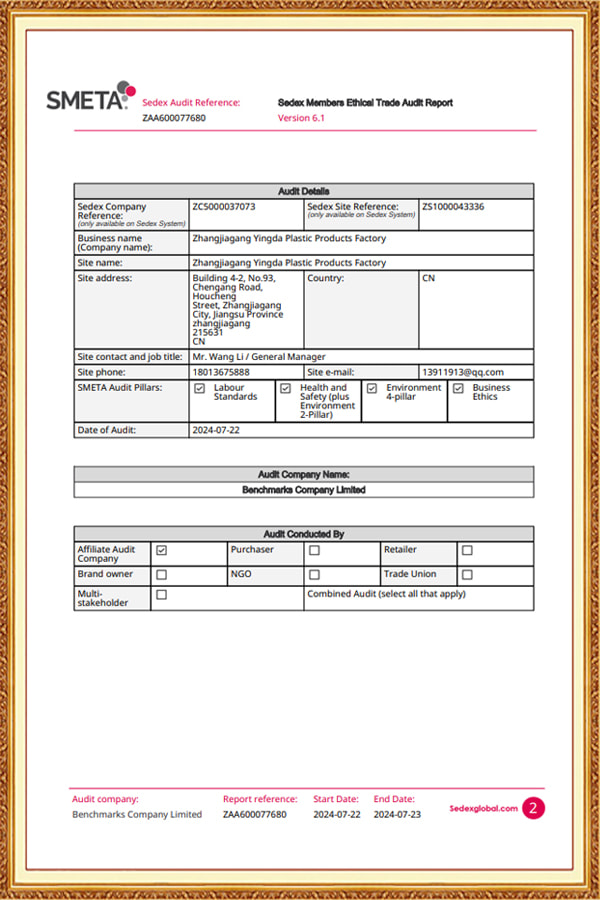

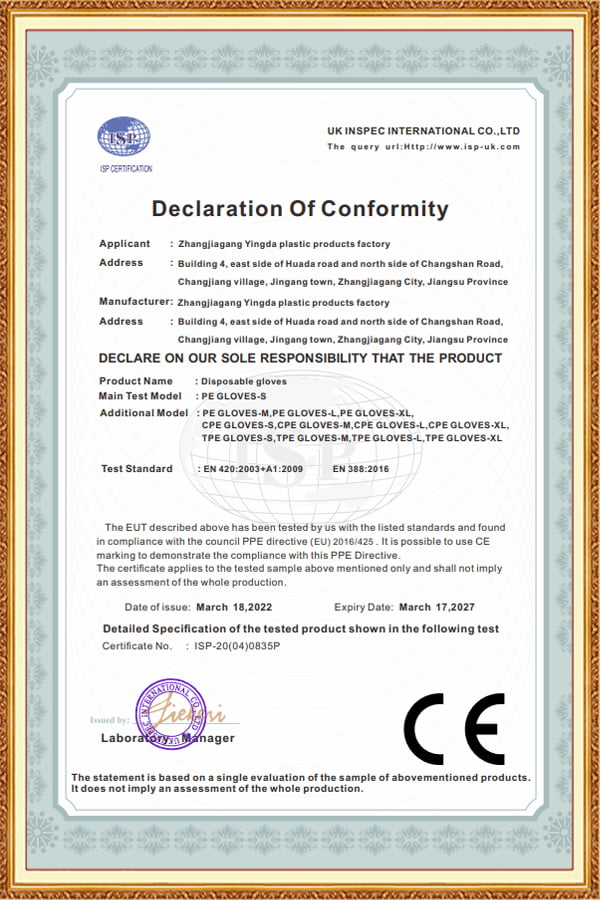

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. From food processing and medical settings to cleaning operations and light manufacturing, disposable gloves have become ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory research, hospitality, and industrial manufacturing. Among the most widely used protective garments are polyethylene aprons a...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, polyethylene film has become an indispensable material due to its unique balance of strength, flexibility, chemical resistan...

READ MORE

Why is the surface of diamond textured disposable TPE gloves designed with raised diamond patterns?

The diamond pattern can effectively increase the friction between the gloves and the surface of the object, especially when grasping a wet or smooth surface, allowing the user to grasp the object more firmly. In the food processing industry, when workers handle food with water stains on the surface, the TPE diamond pattern gloves produced by Zhangjiagang Yingda Plastic Products Factory can ensure the stability of the operation and prevent the food from slipping. This is due to its unique pattern design. After precise production under the advanced production line layout, the size and shape of each diamond pattern are strictly controlled to ensure the best grip. This raised pattern design disperses the pressure on the gloves during use, reduces local wear, and thus extends the service life of the gloves. In the field of electronic manufacturing, workers frequently operate electronic components. Yingda Plastic Products Factory has improved the production process through continuous technological innovation, making the diamond pattern of the gloves more wear-resistant and less likely to break during long-term use, reducing the frequency of glove replacement and improving work efficiency. Compared with ordinary flat gloves, diamond patterns make the gloves look more layered and unique. While meeting functional requirements, it also improves the overall aesthetics of the product. With its strong product customization capabilities, Yingda Plastic Products Factory can customize the size and density of diamond patterns according to customer needs, which not only meets the requirements of different customers for the appearance of gloves, but also ensures product quality, making it unique in the field of plastic products.

What impact does the flexibility and elasticity of diamond textured disposable TPE gloves have on the wearing experience?

Diamond textured disposable TPE gloves have excellent flexibility and elasticity, can fit the contour of the hand closely, and provide a comfortable wearing experience like a second layer of skin. In the field of healthcare, medical staff need to wear gloves for a long time to perform various operations. The diamond textured disposable TPE gloves produced by Zhangjiagang Yingda Plastic Products Factory have good flexibility and elasticity, which allows medical staff to move their hands freely during the operation without feeling tight or restrained, greatly reducing hand fatigue. This elasticity can also adapt to people with different hand shapes, whether they have big hands or small hands, they can find the right comfort. Through continuous technological innovation, Yingda Plastic Products Factory continuously optimizes the formula of TPE materials, further improving the flexibility and elasticity of gloves, and taking the wearing experience to the next level.

How does the excellent performance of diamond textured disposable TPE gloves help it be widely used in multiple fields?

Diamond textured disposable TPE gloves have excellent tensile strength, wear resistance and oil resistance, are not easy to break, and are very suitable for food processing environments. Zhangjiagang Yingda Plastic Products Factory's diamond textured disposable TPE gloves have undergone a strict production management model. From mold development to finished products, every link is precisely controlled to ensure that the gloves will not break or penetrate when in contact with various ingredients and greases, ensuring the safety and hygiene of food. Its diamond pattern design enhances grip and facilitates staff to handle ingredients of various shapes and textures. Diamond textured disposable TPE gloves do not contain latex ingredients, will not cause allergic reactions, and are suitable for people who are sensitive to latex. In hospitals and other medical places, Yingda Plastic Products Factory produces high-quality diamond textured disposable TPE gloves through advanced production line layout. Medical staff do not have to worry about allergies when using them. The flexibility and elasticity of the gloves ensure the accuracy of medical operations. Its good tensile strength can also prevent the gloves from being damaged during some more complex medical operations, providing reliable protection for medical staff and patients. Electronic manufacturing has extremely high requirements for product precision and cleanliness. The diamond textured disposable TPE gloves produced by Yingda Plastic Products Factory, with its excellent wear resistance, can effectively prevent the debris generated by the wear on the surface of the gloves from contaminating the electronic components when workers operate precision electronic components. The diamond pattern design of the gloves provides a good grip, allowing workers to more stably pick up and install tiny electronic parts, improving production efficiency and product quality. Moreover, through continuous technological innovation, Yingda Plastic Products Factory can also customize the production of diamond textured disposable TPE gloves according to the special needs of the electronics manufacturing industry to meet the diverse requirements of different customers.

What are the outstanding advantages of the factory in the production of diamond textured disposable TPE gloves?

Zhangjiagang Yingda Plastic Products Factory has a professional R&D team and advanced production equipment, which can customize diamond textured disposable TPE gloves according to the different needs of customers. Whether it is the size, color, or diamond pattern of the gloves, they can be accurately realized. For example, customizing diamond textured disposable TPE gloves with specific colors and patterns of corporate logos for food processing companies not only meets the needs of corporate image promotion, but also ensures the functionality of the gloves. Through a multi-unit support system such as cost control, quality management, and efficiency optimization, it ensures that customized products are of high quality and have good cost performance. The factory has established a full-process production line from mold development, stamping, heat treatment, surface treatment to equipment. When producing diamond textured disposable TPE gloves, every link from raw materials to finished products follows a production management model of precision, specialization, standardization, and refinement. This advanced production line layout makes the production process more efficient and stable, and the product quality is more guaranteed. In the mold development link, through high-precision mold manufacturing, it is ensured that the diamond pattern of each pair of diamond textured disposable TPE gloves is clear and regular, thereby ensuring the grip and durability of the gloves.

English

English  Français

Français  Deutsch

Deutsch