Custom Food Packaging Plastic Wrap Manufacturers

PVC cling film is a common food packaging material, mainly made of polyvinyl chloride (PVC). Due to its production process, a large amount of plasticizers (plasticizers) are added to PVC cling film during the production process. If it is heated or comes into contact with greasy foods during use, the plasticizers may precipitate and enter the food, posing a potential risk to human health. Therefore, PVC cling film is not suitable for high-temperature heating or contact with greasy foods.

Plastic Wrap

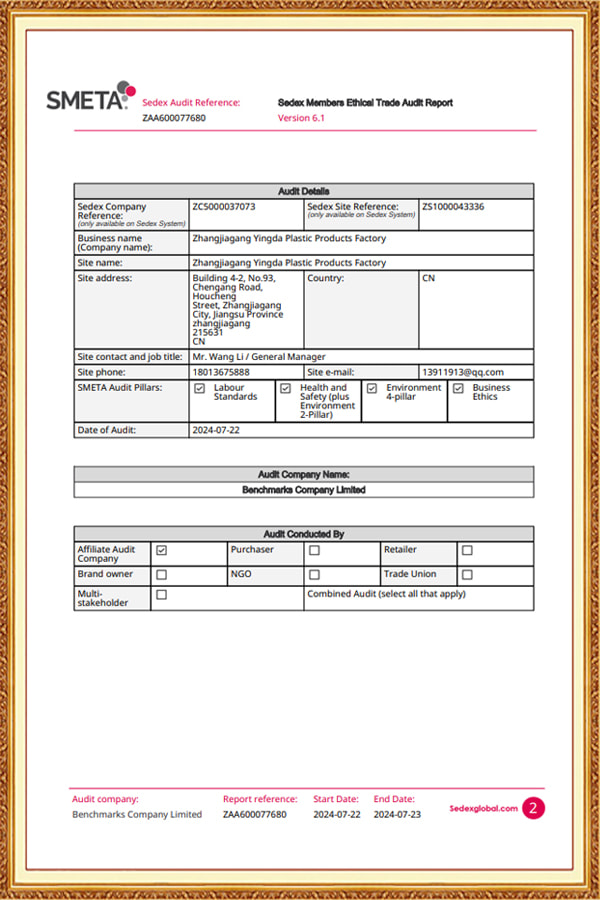

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

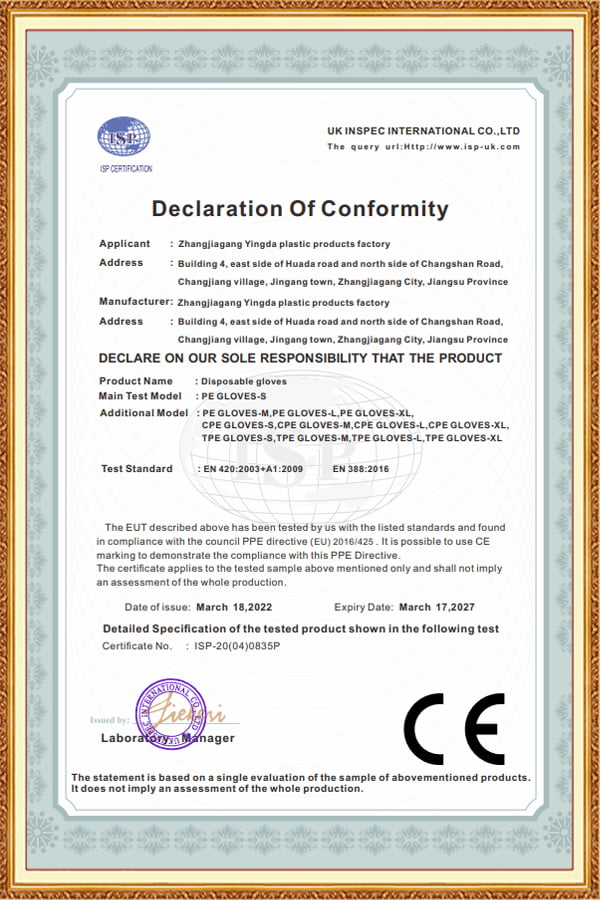

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. From food processing and medical settings to cleaning operations and light manufacturing, disposable gloves have become ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory research, hospitality, and industrial manufacturing. Among the most widely used protective garments are polyethylene aprons a...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, polyethylene film has become an indispensable material due to its unique balance of strength, flexibility, chemical resistan...

READ MORE

How to reduce the residual vinyl chloride monomer (VCM) in the production of PVC cling film for food packaging?

In the field of food packaging, PVC cling film is widely used, but the problem of residual vinyl chloride monomer (VCM) in its production process has always attracted much attention. VCM has certain toxicity. If the residual amount exceeds the standard, it may cause harm to human health. Therefore, in the production of PVC cling film, it is very important to effectively reduce the residual VCM.

Controlling the source of the production process is the key to reducing VCM residue. In the polymerization reaction stage, the polymerization process and catalyst should be reasonably selected. For example, when using the suspension polymerization method, it is necessary to strictly control the polymerization temperature, pressure and time and other parameters to ensure that the polymerization reaction is fully carried out so that more vinyl chloride monomer is converted into polyvinyl chloride, thereby reducing the residual amount. At the same time, the selection of efficient catalysts can increase the reaction rate and conversion rate and reduce the monomer residue.

Optimizing the monomer removal process after the polymerization reaction should not be ignored. At present, the commonly used monomer removal methods include steam stripping and vacuum degassing. Taking stripping as an example, by introducing inert gas (such as nitrogen) into the polymer system, VCM is volatilized from the polymer and then recovered by condensation. During the stripping process, the stripping temperature, gas flow rate and residence time should be controlled to improve the efficiency of stripping. Vacuum degassing is to reduce the boiling point of VCM under negative pressure conditions, making it easier to escape from the polymer. It should be noted that different stripping processes are suitable for different production scales and product requirements. The appropriate process should be selected according to the actual situation, and the process parameters should be optimized.

The selection of raw materials also affects the amount of VCM residue. Zhangjiagang Yingda Plastic Products Factory uses new raw materials that meet food grade standards, which is worth learning from. The VCM content in high-quality raw materials is low and has few impurities, which helps to reduce residues from the source. When purchasing raw materials, suppliers should be strictly screened and required to provide quality inspection reports for raw materials to ensure that the raw materials meet relevant standards.

The quality control system in the production process is indispensable. The company strictly follows the procedures and requirements of the quality control management system, and a complete quality control process should also be established in the production of PVC cling film. From the entry of raw materials to the exit of finished products, each link must be strictly tested. For example, after the polymerization reaction, the VCM residue in the polymer is tested. If the residue is found to exceed the standard, the production process is adjusted in time; in the finished product inspection stage, the VCM residue is tested again to ensure that the product meets the national standards.

The cleaning and maintenance of production equipment can also indirectly affect VCM residue. Clean the production equipment regularly to prevent the VCM residue in the equipment from polluting subsequent production. At the same time, maintain the operating status of the equipment to ensure the stability of the production process and avoid fluctuations in the production process due to equipment failure, thereby affecting the VCM residue.

In addition, advanced detection technology can be introduced to monitor the VCM residue in the production process in real time. Through online detection equipment, timely understand the changes in VCM residue, so as to quickly adjust the production process and ensure product quality.

Zhangjiagang Yingda Plastic Products Factory has strong product customization capabilities and has built a multi-unit support system for cost control, quality management and efficiency optimization. Its full-process production line ensures the accuracy of each link from mold development to assembly. In the production of PVC cling film, we can learn from its professional, standardized and refined production management model, implement various measures to reduce VCM residues in each production link, strengthen the coordinated management of each link, and improve production efficiency and product quality.

English

English  Français

Français  Deutsch

Deutsch