Custom LDPE Disposable Gloves Manufacturers

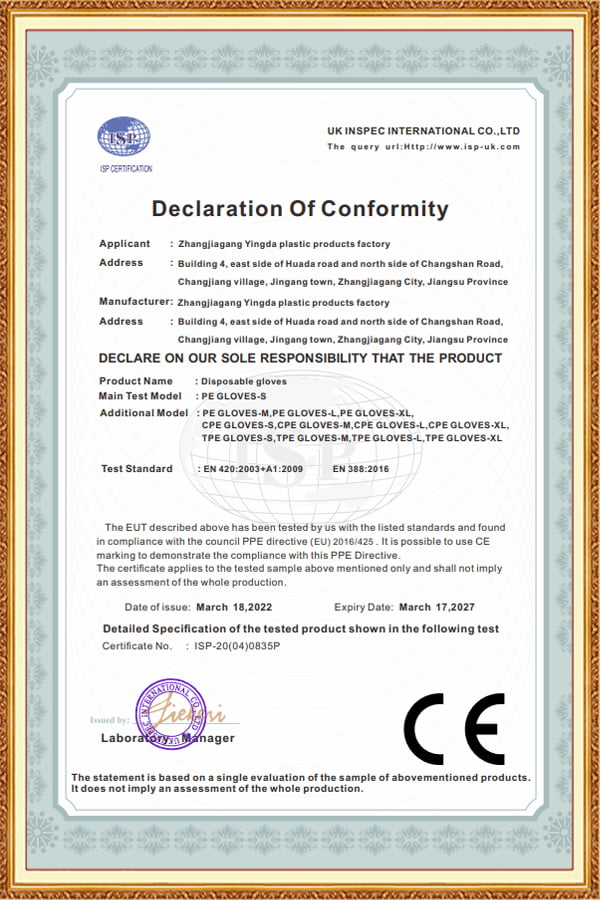

LDPE gloves (low-density polyethylene gloves) are soft and flexible disposable gloves with good touch and elasticity, suitable for tasks that require delicate operations. They are soft, comfortable to wear, fit the shape of the hand, and provide excellent dexterity and freedom of hand movement. LDPE gloves are usually thicker, so they excel in tear strength, while also having a certain degree of durability and being able to effectively prevent punctures and tears. This type of glove is widely used in food processing, cleaning, beauty salons, household hygiene and other scenarios because of its transparent design, which is easy to observe, easy to handle and clean, and has good water and oil resistance. LDPE gloves are also environmentally friendly and recyclable, meeting the requirements of sustainable development.

LDPE Gloves

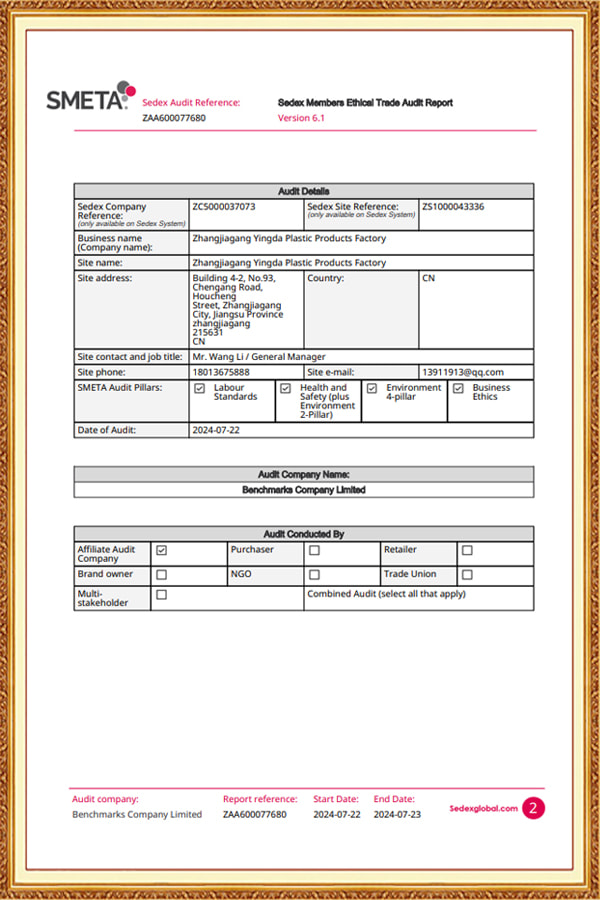

Associated Company: Zhangjiagang Meilida Medical Products Co., Ltd

-

Introduction In today’s fast-paced industrial and commercial environments, protective handwear must strike a careful balance between safety, comfort, hygiene, and cost efficiency. From food processing and medical settings to cleaning operations and light manufacturing, disposable gloves have become ...

READ MORE -

Introduction Protective apparel plays a vital role in maintaining hygiene, safety, and regulatory compliance across industries such as food processing, healthcare, laboratory research, hospitality, and industrial manufacturing. Among the most widely used protective garments are polyethylene aprons a...

READ MORE -

Introduction Polyethylene film is one of the most widely used plastic materials in modern industry. From packaging and agriculture to construction and protective applications, polyethylene film has become an indispensable material due to its unique balance of strength, flexibility, chemical resistan...

READ MORE

Why are low-density polyethylene gloves, LDPE disposable gloves popular in the disposable gloves market?

Excellent physical properties: low-density polyethylene gloves, LDPE disposable gloves are made of low-density polyethylene, which gives the gloves soft and flexible properties, fits the hand shape, and provides excellent flexibility and freedom of hand movement, especially suitable for tasks that require delicate operations. During the assembly of electronic products, workers wearing low-density polyethylene gloves, LDPE disposable gloves can flexibly grasp and install tiny parts without affecting the accuracy of operations due to the constraints of the gloves. Low-density polyethylene gloves, LDPE disposable gloves are usually thicker and have excellent tear resistance. After testing, when subjected to a certain tension and friction, they are less likely to break than other gloves of the same material, effectively preventing punctures and tears during work, and ensuring the safety of the user's hands.

Good protective performance: It has good waterproof and oil resistance, which makes it perform well in scenes such as food processing and cleaning that are easily exposed to water and oil. In the food processing industry, when handling meat, seafood and other ingredients, it can effectively block blood, grease, and prevent hand contamination, while also preventing hand bacteria from contaminating food. After ATP bioluminescence detection, the total number of colonies on the operating table can be greatly reduced after use. Moreover, the transparent design of the gloves makes it convenient for users to observe the hand operation at any time, and it is also convenient for handling and cleaning.

Environmentally friendly and sustainable: low-density polyethylene gloves, LDPE disposable gloves are environmentally friendly and recyclable, which meets the current global sustainable development requirements. With the increase in environmental awareness, more and more companies and consumers tend to choose environmentally friendly products. Low-density polyethylene gloves, LDPE disposable gloves can be processed through a specific recycling process after use and reprocessed into other plastic products, reducing the burden on the environment. This advantage makes it more competitive in the market.

What are the unique features of low-density polyethylene gloves, LDPE disposable gloves in different industries?

Food processing industry: In the food processing link, employees wearing low-density polyethylene gloves, LDPE disposable gloves can effectively block hand microorganisms from contaminating food and ensure food safety. During the production of baked goods, gloves can prevent hand oils and bacteria from mixing into dough and other raw materials, affecting the taste and quality of the food. When handling shelled seafood, its puncture resistance can maintain continuous operation for a long time without damage, ensuring the safety of workers' hands. Some chain catering companies have incorporated it into the standardized operating procedures and implemented double protection in conjunction with the HACCP system to ensure that every link from food processing to serving meets hygiene standards.

Beauty and hairdressing industry: In hair dyeing operations, low-density polyethylene gloves, LDPE disposable gloves can block phenylenediamine chemicals from contacting the skin. Verified by a third-party testing agency, the blocking efficiency of oxidative hair dyes is as high as 98%, effectively protecting the hand skin of hairdressers and customers. Its thickened design can extend the effective protection time and meet the needs of a single hair dyeing process.

In the field of household hygiene: When handling fresh food, low-density polyethylene gloves, LDPE disposable gloves can reduce the risk of cross-contamination of foodborne pathogens such as Salmonella. For example, when handling vegetables after handling raw meat, gloves can prevent bacteria from spreading from raw meat to vegetables. In cleaning operations, its solvent resistance can resist the corrosion of common cleaning agents such as 84 disinfectants and detergents, protect the skin of the hands from harm, and make household cleaning work safer and easier.

What technical advantages does the factory have in the production of low-density polyethylene gloves, LDPE disposable gloves?

Zhangjiagang Yingda Plastic Products Factory has established a full-process production line from mold development, stamping, heat treatment, surface treatment to equipment. In the mold development stage, advanced technology is used to accurately design the glove mold to ensure that the size of each pair of gloves is accurate and fits the hand shape. High-precision stamping equipment is used in the stamping process to ensure the molding quality of the gloves. Heat treatment and surface treatment processes improve the physical properties and appearance quality of the gloves, making the gloves more durable and more beautiful. The entire production process follows a precise, professional, standardized and refined production management model. Every link from design to finished product is strictly controlled to ensure stable and reliable product quality, which is unique in the field of plastic products. Zhangjiagang Yingda Plastic Products Factory continues to invest in R&D resources for technological innovation. In terms of material formulation, the flexibility and tear resistance of gloves are improved by optimizing the ratio of LDPE materials. New production processes are introduced, such as improved blow molding processes, to make the film thickness of gloves produced more uniform and the performance more stable. In the quality inspection link, advanced automated testing equipment is used to quickly and accurately detect the thickness, strength, waterproofness and other indicators of gloves, ensuring that every pair of gloves shipped meets high quality standards.

How does the factory achieve personalized customization of low-density polyethylene gloves, LDPE disposable gloves?

Zhangjiagang Yingda Plastic Products Factory has strong product customization capabilities. Whether it is the size, color, or special functional requirements of the gloves, it can meet the personalized requirements of customers. Gloves of different thicknesses can be customized for customers in different industries. The food processing industry can choose thicker gloves with stronger puncture resistance; the beauty and hairdressing industry can customize softer and more fitting gloves. In terms of color, in addition to the common transparent color, gloves of specific colors can also be customized according to customer brand requirements to enhance brand recognition. Mastering key processes and technologies is the basis for achieving personalized customization. During the production process, the performance and appearance of gloves can be customized by adjusting the raw material formula, mold parameters and production process. In order to meet the needs of some industries with extremely high hygiene requirements, a special sterilization process can be used to produce sterile-grade low-density polyethylene gloves and LDPE disposable gloves. For application scenarios that require enhanced anti-slip performance, the friction of the glove surface can be increased by improving the glove surface treatment process.

English

English  Français

Français  Deutsch

Deutsch